Gerty WardJuly 28, 2008After a Sunday supper of turkey with all the trimmings, the WHOI team and the LSSL deck crew prepares the mooring to go back out into the Arctic Ocean for another year.

Electronics are checked, batteries replaced, sediment traps reset, and glass balls prepared. Then the whole thing goes back in the ocean, in reverse order. First the anchor goes in, 4000 pounds of deadweight. Attached to the anchor is the release hook, and the back-up. The WHOI guys make careful note which release they put on which mooring anchor, so they have the correct release codes next year.....

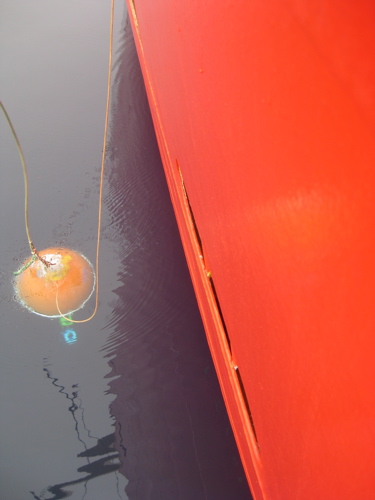

Then the glass balls in hard hats, 58 of them, get hooked on the line, 4 at a time. This process takes well over an hour and looks like a well-rehearsed ballet. Will is careful to connect each set of hardhats properly so the line remains intact over the coming year. The sediment traps go in, then the sensors and finally the top float.

Once the surface buoy is dropped from the ship, it quickly falls the remaining 50 meters so that the anchor is, finally, on the bottom with all the parts strung out above it.

And that is all there is to it. Yeah, right. The whole process takes about 8 hours and there are a zillion other details. I will leave you with one: because these moorings are deployed in ice conditions, they are put in linearly, anchor first. By contrast, when moorings are put in clear ocean (no ice), the parts of the mooring are strung out across the ocean by the ship, and the anchor is dropped in last, taking 45 minutes to fall to the bottom, pulling the other parts in with it. With ice around, this cannot be done. So the anchor goes in first, all 4000 pounds. Working with this much weight and tension on the line makes these mooring deployments a bit more tricky. Last updated: October 7, 2019 | |||||||||||||||||||||||||||||||||||

Copyright ©2007 Woods Hole Oceanographic Institution, All Rights Reserved, Privacy Policy. | |||||||||||||||||||||||||||||||||||